Food quality control is a critical aspect of the food industry. Ensuring that the products that reach our plates are safe and meet quality standards is essential to protect the health of consumers and maintain the reputation of companies. In this article, we will explore the relevance of food quality control and how it is carried out in the industry, including the use of metal detectors and specialised machinery.

THE IMPORTANCE OF FOOD QUALITY CONTROLv

by marketing on 19 de October de 2023

The importance of food quality control

What is food quality control?

Food quality control refers to a set of processes and techniques used to ensure that food products are safe for human consumption and meet established quality standards.

It covers all stages of production, from the procurement of raw materials to the distribution of finished products.

It covers all stages of production, from the procurement of raw materials to the distribution of finished products.

Importance of ensuring food quality

Food safety and quality are essential to protect the health of consumers. Eating contaminated or low-quality food can have serious health consequences, such as food poisoning and foodborne illness. In addition, consumers expect the products they buy to be tasty, fresh and to meet their expectations in terms of taste and texture.

Avoiding risks with metal detectors in the food industry

One of the key aspects of food quality control is the detection of contaminants, such as metal particles, which may be present in food products. These contaminants can enter during the production process, either through the machinery used or the raw materials.

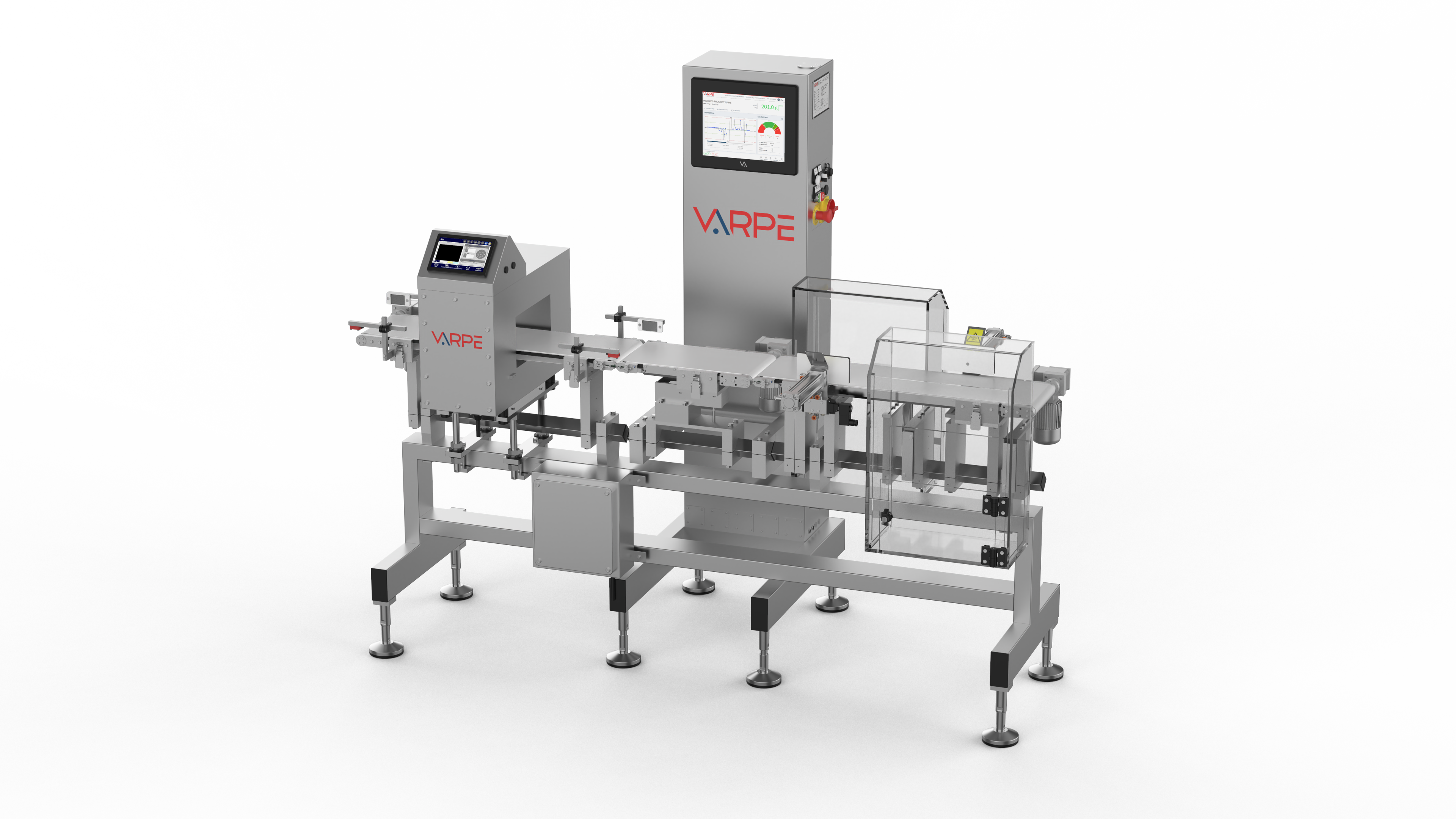

To address this problem, the food industry uses specially designed metal detectors. These devices are able to identify minute metal particles in food and eliminate any potential health risk to consumers.

Metal detectors in the food industry work by emitting an electromagnetic field through a conveyor belt transporting food products. If the presence of metal is detected, the system emits an alarm signal and stops the production line, allowing the contaminant to be removed before it reaches the end consumer.

To address this problem, the food industry uses specially designed metal detectors. These devices are able to identify minute metal particles in food and eliminate any potential health risk to consumers.

Metal detectors in the food industry work by emitting an electromagnetic field through a conveyor belt transporting food products. If the presence of metal is detected, the system emits an alarm signal and stops the production line, allowing the contaminant to be removed before it reaches the end consumer.

Quality control equipment

In addition to metal detectors, quality control machinery plays a crucial role in the food industry. This machinery includes equipment such as x-ray inspection machines, weighing and measuring systems, and machine vision systems. Each of this equipment is used to ensure that products meet established quality standards and are free of defects.

X-ray inspection, for example, allows the detection of foreign objects inside food products, such as bones, plastics or unwanted materials. This is especially important in packaged products, where contaminants can be difficult to detect with the naked eye.

Weighing and measuring systems ensure that products have the correct weight and dimensions, which is essential for proper packaging and labelling. These systems also help prevent wastage of raw materials by ensuring that products conform to specifications.

Artificial vision, meanwhile, allows inspection of the appearance of products, identifying visual defects such as discolouration or irregularities in shape. This is especially relevant in fresh and packaged food production, where product appearance plays an important role in the consumer's purchasing decision.

X-ray inspection, for example, allows the detection of foreign objects inside food products, such as bones, plastics or unwanted materials. This is especially important in packaged products, where contaminants can be difficult to detect with the naked eye.

Weighing and measuring systems ensure that products have the correct weight and dimensions, which is essential for proper packaging and labelling. These systems also help prevent wastage of raw materials by ensuring that products conform to specifications.

Artificial vision, meanwhile, allows inspection of the appearance of products, identifying visual defects such as discolouration or irregularities in shape. This is especially relevant in fresh and packaged food production, where product appearance plays an important role in the consumer's purchasing decision.

Compliance with regulations and standards

Food quality control is not only about ensuring safety and quality, but also about complying with regulations and standards set by the competent authorities. In Spain and in the European Union in general, there are strict regulations governing the production and marketing of food, and companies must comply with these regulations in order to operate legally.

Failure to comply with these regulations can have serious legal and economic consequences for food companies. Quality control is therefore an essential part of business management in this industry.

Failure to comply with these regulations can have serious legal and economic consequences for food companies. Quality control is therefore an essential part of business management in this industry.

Additional benefits of food quality control

In addition to ensuring the safety and quality of products, food quality control brings a number of additional benefits for companies:

Reputation Enhancement

Companies that engage in quality control demonstrate their commitment to customer satisfaction and production excellence. This can enhance their reputation and increase consumer confidence in their products.

Companies that engage in quality control demonstrate their commitment to customer satisfaction and production excellence. This can enhance their reputation and increase consumer confidence in their products.

Cost reduction

Early detection of quality problems can prevent the production of entire batches of defective products, saving time and money.

Early detection of quality problems can prevent the production of entire batches of defective products, saving time and money.

Access to international markets

Meeting internationally recognised quality standards allows companies to export their products to foreign markets, expanding their business opportunities.

Meeting internationally recognised quality standards allows companies to export their products to foreign markets, expanding their business opportunities.

In short, food quality control is essential to ensure the safety and quality of food products reaching consumers. The detection of contaminants through metal detectors and the use of specialised machinery play a crucial role in this process. In addition, compliance with regulations and standards is essential to the success of businesses in the food industry.

Ensuring that the food we consume is safe and of high quality is a goal shared by producers, regulators and consumers. Food quality control is the cornerstone of achieving this goal and maintaining confidence in the food industry.

Ultimately, investing in quality control is not only a legal obligation, but an investment in the health and satisfaction of consumers, which are the foundation for the continued success of any food business.