Precision and reliability in the manufacturing process are fundamental pillars in the pharmaceutical industry. In this context, weight control systems play a crucial role, ensuring that each product not only meets the highest quality standards, but also guarantees the safety and satisfaction of the end consumer. We will explore how these systems are integrated into pharmaceutical processes, their importance and the benefits they bring.

WEIGHT CONTROL SYSTEMS IN THE PHARMACEUTICAL INDUSTRY

by marketing on 2 de April de 2024

WEIGHT CONTROL SYSTEMS IN THE PHARMACEUTICAL INDUSTRY

WHAT ARE WEIGHT CONTROL SYSTEMS?

Checkweighing systems, also known as checkweighers or dynamic weighing systems, are high-tech equipment designed to automatically weigh 100% of the products on a manufacturing line. Their main objective is to verify that the amount of product indicated on the package corresponds exactly to the amount it contains, thus complying with the established specifications and avoiding deviations that could affect the quality or dosage of the product.

IMPORTANCE IN THE PHARMACEUTICAL INDUSTRY

In the pharmaceutical industry, where accuracy is vital, weight monitoring systems ensure the correct dosage of medicines, an imperative for treatment efficacy and patient safety. These systems allow immediate detection of any deviation in weight, which facilitates instant corrective action, minimising the risk of errors.

The importance of weight monitoring systems in the pharmaceutical industry cannot be underestimated, as they play a critical role in maintaining the integrity and efficacy of medicines. In an industry where accuracy is not just a goal, but a must, these systems ensure that every unit of medicine produced meets the strictest quality standards, ensuring correct dosage and thus patient safety.

Accurate dosing of medicines is a cornerstone of the pharmaceutical industry, as even the smallest variations in weight can have significant consequences on patients' health. An underdosed drug may not have the desired therapeutic effect, while an overdose can lead to serious side effects or even toxicity. This is where weight monitoring systems become an indispensable ally, providing accurate, real-time weight verification of each product on the production line.

The importance of weight monitoring systems in the pharmaceutical industry cannot be underestimated, as they play a critical role in maintaining the integrity and efficacy of medicines. In an industry where accuracy is not just a goal, but a must, these systems ensure that every unit of medicine produced meets the strictest quality standards, ensuring correct dosage and thus patient safety.

Accurate dosing of medicines is a cornerstone of the pharmaceutical industry, as even the smallest variations in weight can have significant consequences on patients' health. An underdosed drug may not have the desired therapeutic effect, while an overdose can lead to serious side effects or even toxicity. This is where weight monitoring systems become an indispensable ally, providing accurate, real-time weight verification of each product on the production line.

These advanced weighing systems are equipped with highly sensitive sensors and data processing technology, enabling them to detect any deviation from the established standard weight with millimetre accuracy. This immediate detection capability is crucial, as it enables corrective action to be implemented without delay, either by automatically discarding the defective product or by adjusting the production process to correct the error. In this way, checkweighing systems contribute significantly to reducing the risk of dosing errors, thereby improving patient safety and treatment reliability.

In addition, the implementation of these systems helps pharmaceutical companies to comply with international regulations and quality standards, such as Good Manufacturing Practices (GMP), which are essential for the commercialisation of medicines. Compliance with these regulations is not only a legal requirement, but also serves to reinforce the confidence of healthcare professionals and patients in the brand and its products.

In addition, the implementation of these systems helps pharmaceutical companies to comply with international regulations and quality standards, such as Good Manufacturing Practices (GMP), which are essential for the commercialisation of medicines. Compliance with these regulations is not only a legal requirement, but also serves to reinforce the confidence of healthcare professionals and patients in the brand and its products.

CHARACTERISTICS OF WEIGHT CONTROL SYSTEMS IN THE PHARMACEUTICAL INDUSTRY

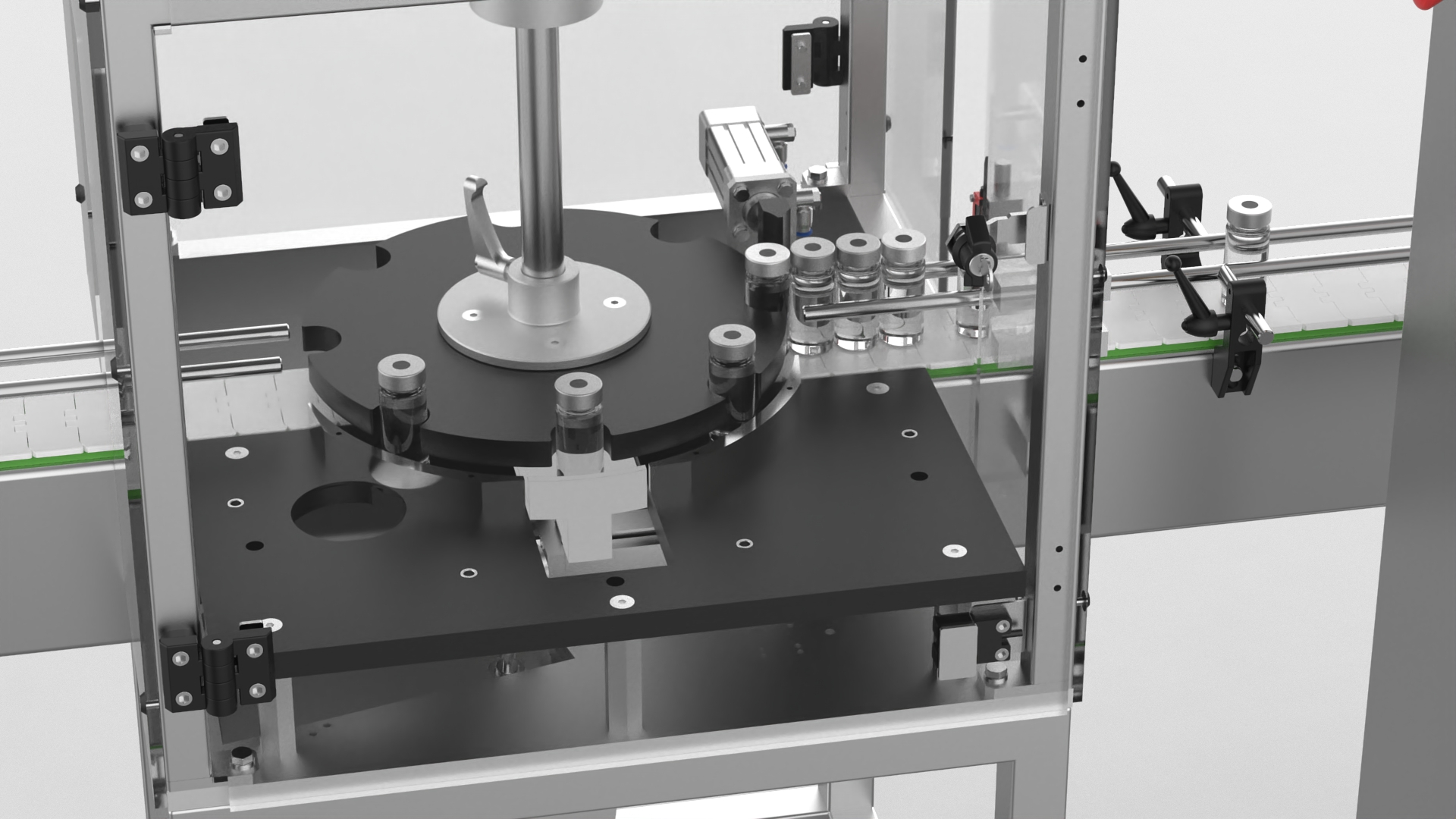

Checkweighing systems for the pharmaceutical industry are characterised by their high precision, flexibility and ability to adapt to different production lines and product varieties. For Varpe, a leading company in the development of these solutions, it is essential to consider certain aspects before choosing the right equipment, such as ease of integration into the existing line, the diversity of products to be processed and the capacity for total production control.

APPLICATION EXAMPLES

A clear example of these systems can be found in the solutions offered by Varpe, which stand out for their ergonomic design, easy installation and start-up, ensuring efficient and reliable control of the weight of pharmaceutical products. This equipment automatically weighs each unit produced, guaranteeing that the amount of product indicated is exactly what is inside the container.

BENEFITS OF IMPLEMENTING WEIGHT MANAGEMENT SYSTEMS

The implementation of weight control systems in the pharmaceutical industry offers multiple benefits, including:

QUALITY ASSURANCE

Ensures that all products meet established weight standards, contributing to the safety and efficacy of medicines.

Ensures that all products meet established weight standards, contributing to the safety and efficacy of medicines.

PRODUCTION EFFICIENCY

Optimises manufacturing processes by early identification of any weight anomalies, reducing waste and improving profitability.

Optimises manufacturing processes by early identification of any weight anomalies, reducing waste and improving profitability.

REGULATORY COMPLIANCE

Facilitates compliance with strict regulations and standards in the pharmaceutical industry, avoiding penalties and ensuring consumer confidence.

Facilitates compliance with strict regulations and standards in the pharmaceutical industry, avoiding penalties and ensuring consumer confidence.

In short, weight control systems are essential in the pharmaceutical industry, not only for their contribution to product quality and safety, but also for their impact on the efficiency and profitability of production processes. Companies like Varpe are leading the way with innovative solutions that adapt to the specific needs of this industry, ensuring that every medicine that reaches the consumer meets the highest standards of quality and accuracy.