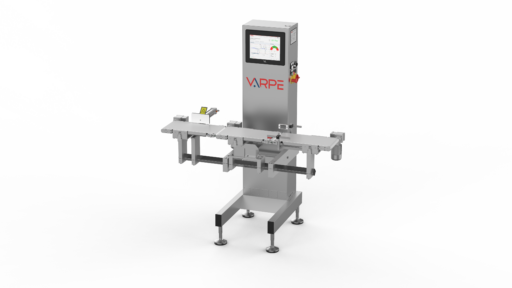

Calibrating a checkweigher is essential in industrial environments to know the quality of the measurement result of the equipment.

ARE MY CHECKWEIGHERS RELIABLE?

by marketing on 7 de March de 2024

WHY IS ACCREDITED CALIBRATION SO IMPORTANT?

01. REGULATORY COMPLIANCE

Calibration provides essential information on the quality of the measurement results required by the regulations and standards applicable to the different industrial sectors.

Calibration provides essential information on the quality of the measurement results required by the regulations and standards applicable to the different industrial sectors.

04. COST SAVINGS

Products to be placed on the market require regular checks which entail costs and resources. If the checkweighers used for such checks have been calibrated by an accredited laboratory, redundant evaluations, and thus the associated costs, are drastically reduced.

Products to be placed on the market require regular checks which entail costs and resources. If the checkweighers used for such checks have been calibrated by an accredited laboratory, redundant evaluations, and thus the associated costs, are drastically reduced.

02. PRODUCT QUALITY

Quality in the supply chain plays a very important role. An accurate checkweigher that has been calibrated by an accredited laboratory helps to guarantee product specifications and requirements.

Quality in the supply chain plays a very important role. An accurate checkweigher that has been calibrated by an accredited laboratory helps to guarantee product specifications and requirements.

05. CONSUMER SAFETY

In industries such as food and pharmaceuticals, consumer safety is a priority. Calibration of the checkweigher by an accredited laboratory reduces the possibility of producing a defective item.

In industries such as food and pharmaceuticals, consumer safety is a priority. Calibration of the checkweigher by an accredited laboratory reduces the possibility of producing a defective item.

03. OPERATIONAL EFFICIENCY

A checkweigher helps optimise production processes by ensuring that batches of products are produced to specification. This reduces waste and improves operational efficiency by preventing over- or under-production.

A checkweigher helps optimise production processes by ensuring that batches of products are produced to specification. This reduces waste and improves operational efficiency by preventing over- or under-production.

06. BRAND REPUTATION

Accredited laboratories bring reliability and recognition, which has a direct impact on brand image.

Accredited laboratories bring reliability and recognition, which has a direct impact on brand image.

HOW IS THE CALIBRATION PROCESS?

01. CONTRACTING THE SERVICE

It is preferable to contract the calibration service to an accredited laboratory.

It is preferable to contract the calibration service to an accredited laboratory.

04. CALIBRATION

Measurement tests are performed to determine the uncertainty of the instrument.

Measurement tests are performed to determine the uncertainty of the instrument.

02. CLEANING

Before calibration it is important to ensure that the checkweigher is in proper condition.

Before calibration it is important to ensure that the checkweigher is in proper condition.

05. RESULTS

The user analyses the results of the calibration to determine whether it meets the required requirements.

The user analyses the results of the calibration to determine whether it meets the required requirements.

03. MASS STANDARDS

Certified mass standards traceable to national or international standards are used.

Certified mass standards traceable to national or international standards are used.

06. CERTIFICATE

A calibration certificate documenting the instrument data is issued, with the guarantee of having the backing of the accreditation body (ENAC or other).

A calibration certificate documenting the instrument data is issued, with the guarantee of having the backing of the accreditation body (ENAC or other).

WHAT DOES AN ACCREDITED CALIBRATION BRING?

| Item | ACCREDITED | NOT ACCREDITED |

|---|---|---|

| It has competent technical staff |

✔ | ✘ |

| Applies the evaluation process appropriate to the type of product, process, service, etc. |

✔ | ✘ |

| It has the necessary technical resources |

✔ | ✘ |

| Maintains the level of independence necessary to act with due impartiality |

✔ | ✘ |

| Undergoes continuous monitoring by its accreditation body |

✔ |

✘ |

ACCREDITED LABORATORY

Varpe has its own laboratory accredited by ENAC for the calibration of dynamic checkweighers from any manufacturer.

TAILOR-MADE CALIBRATIONS

Varpe performs customised calibrations according to the customer's needs in terms of the number of formats, the weight points and the speed at which each one must be calibrated.

QUALIFIED TECHNICAL STAFF

Varpe's technical staff is qualified to perform accredited calibration according to internal procedure based on EMC G-19.