Have you ever wondered how they make sure that the food that reaches your table is safe? Well, food inspection plays a crucial role in this process. In this article, we will look at the different food inspection systems, explaining how they work and why they are so important.

EXAMPLES OF FOOD

INSPECTION SYSTEMS

by marketing on 12 de January de 2024

Examples of food inspection systems

The importance of food inspection

Food safety is an issue that affects us all. Hence the importance of food inspection, which ensures that what we eat is safe and of high quality. Inspection systems detect everything from physical contaminants to microbiological problems, ensuring that food does not pose a risk to our health.

X-ray inspection equipment

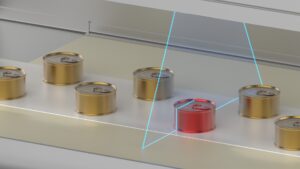

One of the most advanced and revolutionary methods in food inspection is x-ray inspection equipment. These systems use x-rays to "see" through the product. Their ability to detect foreign bodies such as metal, glass, stones and some types of plastics is impressive and crucial for food safety.

But how exactly do they work? X-ray machines emit a beam of X-rays that passes through the food product. As it passes through the food, this beam is attenuated or absorbed to varying degrees depending on the density and composition of the material it encounters. This creates a kind of "fingerprint" of the inside of the product, revealing the presence of contaminants that would otherwise be invisible.

But how exactly do they work? X-ray machines emit a beam of X-rays that passes through the food product. As it passes through the food, this beam is attenuated or absorbed to varying degrees depending on the density and composition of the material it encounters. This creates a kind of "fingerprint" of the inside of the product, revealing the presence of contaminants that would otherwise be invisible.

What is really fascinating about this technology is that it is not limited to detecting contaminants. It also has the ability to assess product integrity. For example, it can verify whether a can of canned food is correctly filled or whether a food package contains all the components in the correct amounts. This is made possible by the ability of X-rays to provide detailed images of the internal structure of the product.

Another important aspect of this equipment is its versatility. They can be used on a wide range of food products, from fruits and vegetables to meats and packaged products. In addition, x-ray inspection technology continues to evolve, incorporating improvements such as faster line speeds, more compact systems and more sophisticated image processing algorithms, allowing for even more accurate and efficient detection.

Metal detection in food

Metal detection in food is an essential component in the food production chain, crucial to ensure product safety and quality. These detectors look for traces of metals that may have been accidentally introduced during the manufacturing process. Their importance is accentuated in environments where many metal machines are used, such as in the canning industry or in meat processing.

The operation of these detectors is based on magnetic fields. When a product passes through the detector, any metal particles disturb the magnetic field, which is detected by the system. This allows the contaminated product to be quickly removed from the production line.

Technological advances have improved these systems, making them capable of differentiating between different types of metals and adjusting their sensitivity according to the product being inspected. This accuracy is vital for products with high salt or moisture content, which can interfere with detection.

The operation of these detectors is based on magnetic fields. When a product passes through the detector, any metal particles disturb the magnetic field, which is detected by the system. This allows the contaminated product to be quickly removed from the production line.

Technological advances have improved these systems, making them capable of differentiating between different types of metals and adjusting their sensitivity according to the product being inspected. This accuracy is vital for products with high salt or moisture content, which can interfere with detection.

Visual and manual inspection

Although technology is a great ally, visual and manual inspection should not be underestimated. This method relies on the human eye and touch to identify irregularities in food. It is often used in conjunction with other technologies to ensure thorough quality control.

Combined inspection systems

In the ideal world, several food inspection systems are combined to obtain the best results. For example, a production line might have a metal detector followed by x-ray inspection equipment and ending with a manual check. This combination maximises the detection of anomalies, ensuring that the food we consume is safe.

Challenges and developments in food inspection

Challenges include keeping up with new technologies and adapting to different types of food products. However, advances in this field are constant, and more accurate and efficient systems are being developed every day.

The future of food inspection

Looking ahead, we can expect to see advances in artificial intelligence and machine learning applied to food inspection. This could mean systems that are faster, more accurate and able to automatically adapt to different types of food.

Food inspection is a fascinating and essential field for our health and safety. From x-ray inspection equipment to metal detection in food, these systems play a vital role in ensuring that the food that reaches our tables is safe. So, the next time you bite into an apple or open a can of preserves, remember that it has gone through a meticulous inspection process to ensure its quality.